The Customer Challenge

The Dartronics Engineers created a customized automated case forming and closing packing system for a customer who was unhappy with the performance of their current equipment and wanted to duplicate their disinfectant wet wipes packing line. The customer wanted the design and layout similar to their existing system, except 4′ longer.

Application Details:

-

-

- For a given batch, the case type will remain the same.

- Disinfectant Wet Wipes Packages will be manually case-packed by three or four operators.

- Wet Wipe line speeds 120 packages/min, and 6 of them are packed into a case.

- Finished Case Line Speeds to be about 20 cases/min.

-

Our Solution:

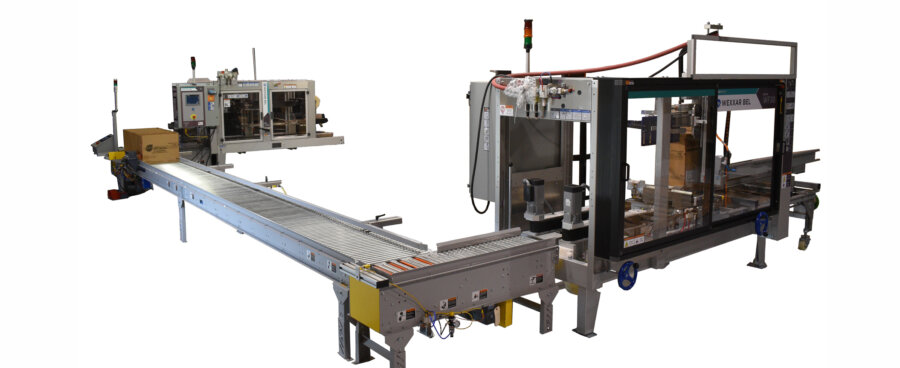

After reviewing the customers’ requirement, the Dartronics team came up with a design to provide a PLC controlled powered roller conveyor system to facilitate manual case packing by three or four operators & integrate it with a standard Wexxar Bel WF30T Fully Automatic Tape Case Former and the Bel 290 Top Automatic Case Sealer machines:

System Shown with Operators

Application Details:

-

-

- A WexxarBel WF30 will erect the cases and seal the bottom with tape. This bottom sealed tape will be received by Powered Roller Conveyor 1.

- The case will then be transferred onto Powered Roller Conveyor 2 via a pneumatic popup transfer for manual loading by 3 or 4 operators.

- The operators will pick flow-wrapped wet wipe packages from a conveyor overtop of Powered Conveyor 2 and manually case pack them.

- Operator 3 will control the release of cases on Conveyor 3. A pneumatically controlled case release system along with roller breaks and case side hold down were engineered to release only one case at a time onto Conveyor 3. Back pressure from filled cases was a major challenge to overcome.

- The filled cases will be transferred onto conveyor 3 via popup transfers.

- The filled cases will lead into the Bel 290 case taper, where the top flaps of the cases will be closed automatically and sealed.

- For a given batch, the case type will remain the same.

- Line Speeds: About 20 cases/min · Conveyor Speeds Required: 100 fpm – Variable Speed

-

Our customized automated case forming and closing packing system helped the customer in various ways; first, it eliminated the need for additional case packers during the height of the Covid-19 pandemic. Second, it restored their confidence in their purchased machinery –they believed their existing Wexxar Bel machines were malfunctioning, but our team corrected the issue by replacing the standard tape heads. And lastly, we saved our customer time. Not only by increasing their case cases per minute, but the entire project was designed, built, tested, and fully integrated in-house by the Dartronics team in under THREE MONTHS!

Constant customer feedback, efficient project management, dedicated engineers, and experienced technicians helped pull all of this together in such a short time.

The entire system was shipped to the customer as a kit along with assembly instruction, and the customer was able to install, test, validate and run production on their own.

For more info on the above project, or if you have one in mind, call and speak to our Engineers now for a free evaluation! Our expert team is here to help make your line simpler to operate, with faster speeds that will increase your ROI. ![]() Take A Free Evaluation!. Email us at Sales@dartronics.com or Call Dartronics at +1 (800) 298-8936 for more info.

Take A Free Evaluation!. Email us at Sales@dartronics.com or Call Dartronics at +1 (800) 298-8936 for more info.