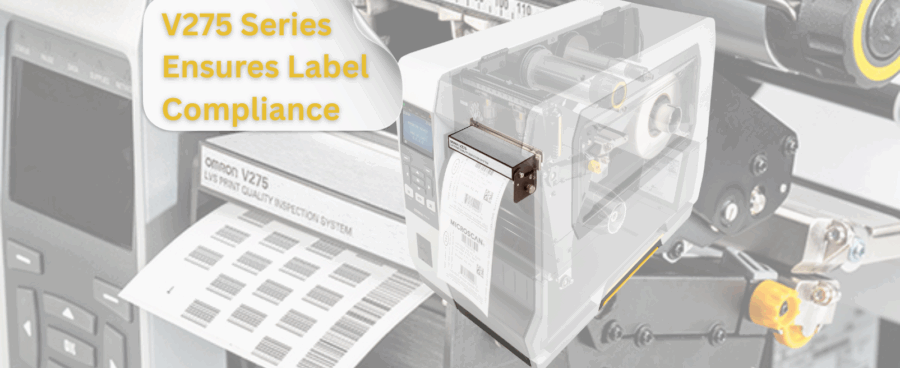

The V275 inspection system ensures label compliance and print quality. The V275 series barcode in-line verifier is not merely a tool but an essential asset for any organization seeking excellence in barcode quality grading, specifically engineered for Zebra thermal printers. This remarkable system guarantees unwavering compliance with prestigious ISO 15426 and GS1 standards, empowering businesses to navigate the intricate maze of industry regulations, including those imposed by the Food and Drug Administration (FDA), with absolute confidence. Imagine the reassurance that comes from comprehensive inspection reports generated for every label, ensuring that each one meets the highest standards of regulatory compliance. With this system in place, you can rest assured that no product will leave your facility with defective labels, significantly enhancing your quality assurance measures. This strengthens your operational capabilities and cultivates a culture of reliability and trust throughout your supply chain. By adopting this excellence and solution, you are choosing to elevate your company’s standards, instilling profound confidence in the quality of your products. Take the step towards unparalleled quality and reliability—your customers will thank you for it.

Discover an unparalleled inspection solution that sets a new standard for quality control: the cutting-edge Zebra printer (models ZT610 and ZT620). With its factory-integrated floating head inspection camera and sophisticated inspection software, this system offers real-time, comprehensive label inspection, ensuring every detail meets the highest standards. Seamlessly integrate this system into your existing operations with Ethernet-based communication between the inspection unit and your PC or server, enhancing efficiency and data management. The intuitive web user interface (UI) empowers users with easy navigation for configuration, live label viewing, data archiving, user management, and detailed audit trails, making complex tasks effortless and effective. Whether your needs include continuous label printing, single label tear-off, or the convenience of peel-and-present functionality, this versatile solution has you covered. Backed by advanced label inspection design tools that fully comply with ISO and GS1 standards, it boasts precise syntax checking, reliable optical character recognition (OCR), optical character verification (OCV) for alphanumeric characters, and meticulous blemish detection for symbols, logos, and all label content.

With an ISO 15426 Declaration of Conformity included, you can be confident that V275 meets and exceeds the demanding standards required for barcode verification. Moreover, our flexible API allows for seamless integration of inspection data into your existing software applications, maximizing efficiency and functionality. Enhance your operational safety with the optional Ethernet-based light tower, providing clear visual alarms for instant notifications. Plus, for those in regulated environments, our Installation Qualification/Operational Qualification/Performance Qualification (IQ/OQ/PQ) package ensures compliance with CFR 21 Part 11, giving you peace of mind that your processes are fully validated.

Imagine the possibilities of networking multiple printers to a single PC or server, streamlining your printing processes and boosting productivity. With this remarkable inspection solution, elevate your operations to new heights and ensure every label reflects your commitment to excellence:

Watch V275 Inspection System Ensure Label Compliance:

V275 Inspection System Key Benefits:

- Slash Inspection Costs: By optimizing your processes, you can dramatically reduce inspection expenses, channeling those savings into more productive areas of your business.

- Spot Defects Early:** Take a proactive approach to identify and address flaws before they reach your customers, ensuring that only the finest products leave your facility.

- Guarantee Unmatched Quality:** Build a strong reputation by implementing a quality assurance system that consistently exceeds expectations, fostering loyalty and trust among your clientele.

- Eliminate Rework:** Save time and money by minimizing the need for rework, allowing your team to focus on delivering exceptional results without unnecessary delays.

- Manage Waste Efficiently:** Adopt effective waste management practices that not only cut costs but also contribute to environmental sustainability, setting your business apart as a responsible choice.

- Reduce Compliance Risks:** Strengthen your operation by proactively addressing compliance issues, protecting your brand’s integrity and ensuring smooth adherence to industry standards and regulations.

For more info on the V275 Series Barcode In-Line Verifier and Print Quality Label Inspection System, email: sales@dartronics.com or call: Dartronics at +1 (800) 298-8936.

OUR COMPANIES

Visit our company sites that highlight specialized machinery.